Ideal Tips About How To Repair A Pcb Board

This may include melting down similar materials to reshape or modify the board, or can sometimes even call for.

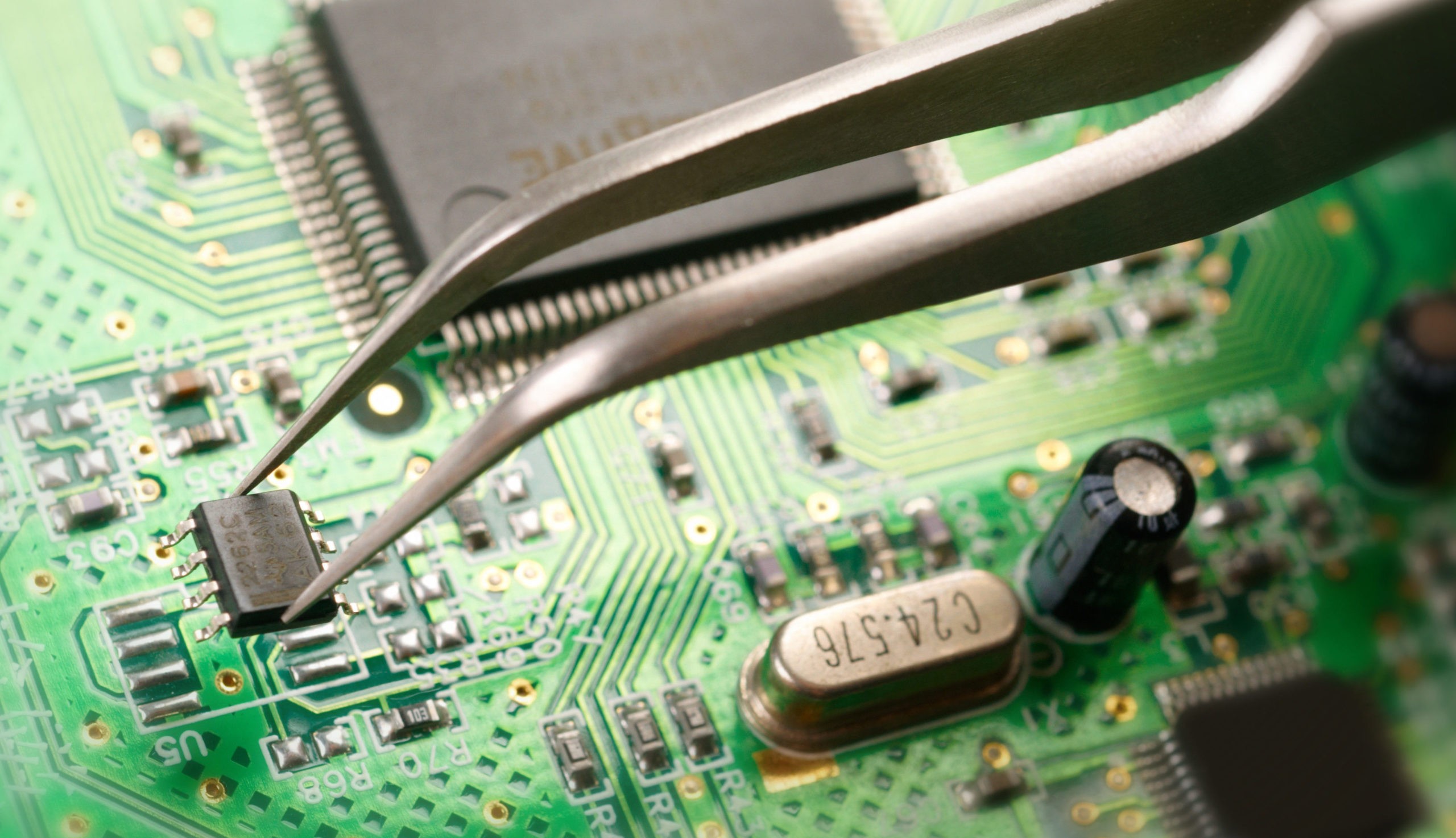

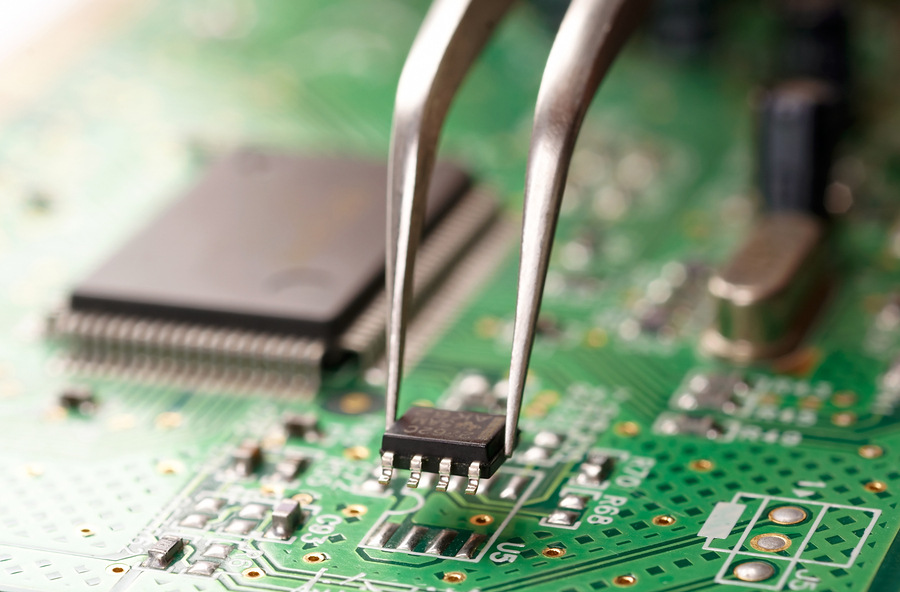

How to repair a pcb board. Once the area is clean, dry away the alcohol with compressed air. For physical or visible damage to a board, base board repair is necessary. Remove damaged pads or components.

Circuit board medics can repair your kenmore w10219462 or w10219463 control board with a 1 business day turnaround and includes a 1 year warranty! First, fix the pcb to your work surface to avoid moving around while working. Tape it to the surface from the sides so that it does not move while you are working on it.

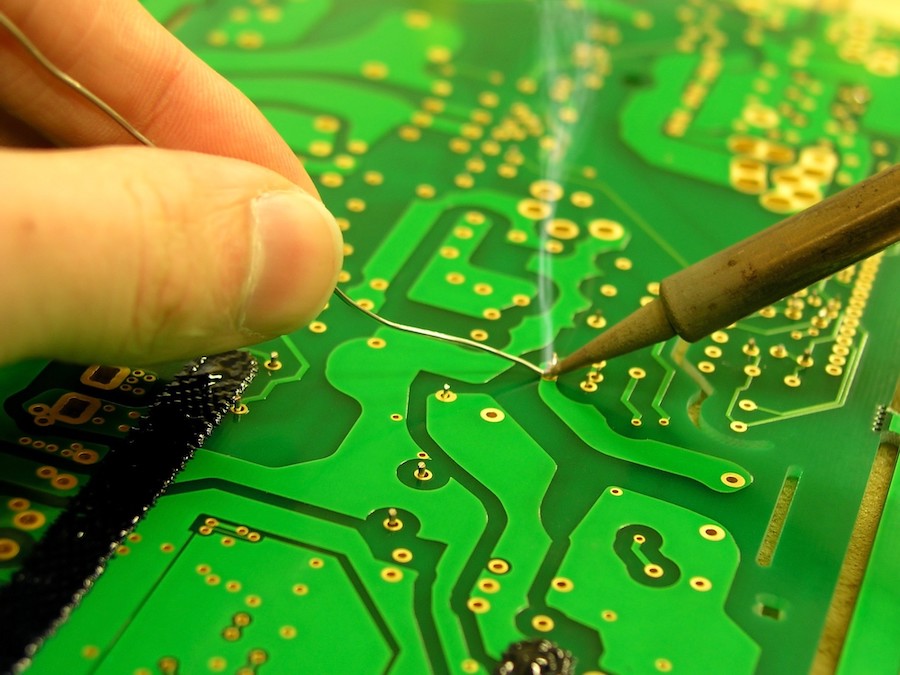

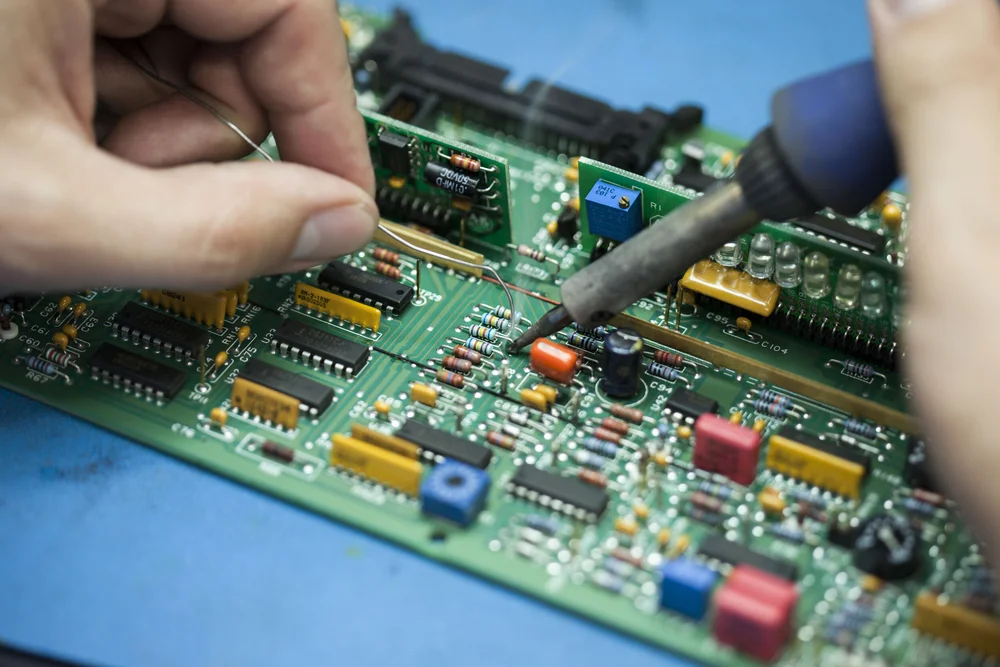

Here are a few h. 2 place the circuit board on a flat surface. You need a hot air gun to remove the defective component from the printed circuit board.

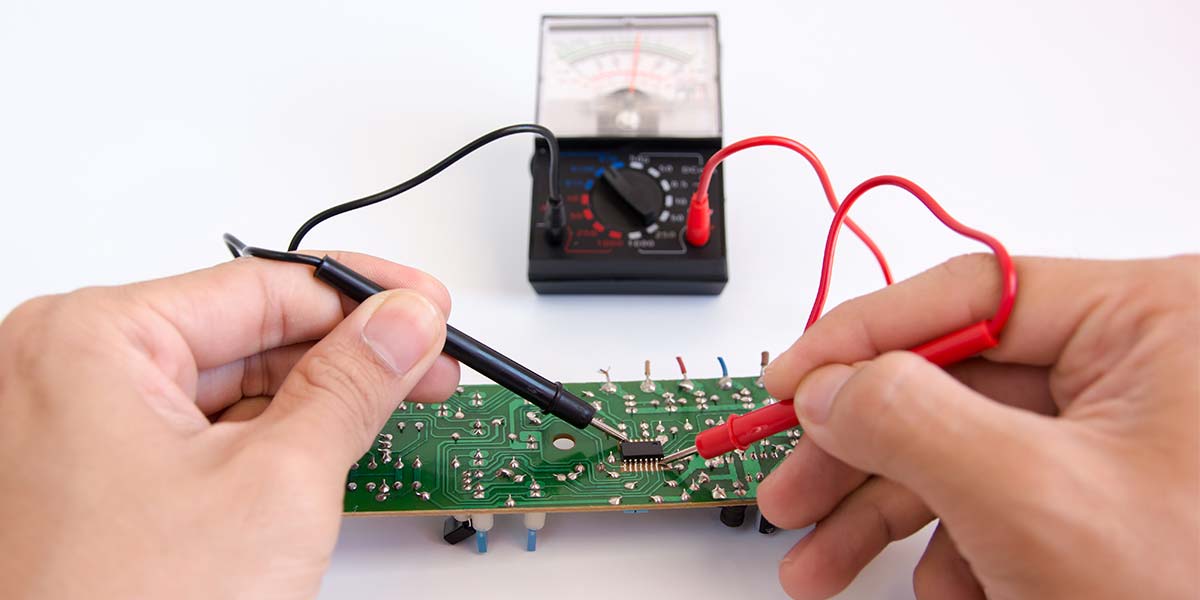

Once the hot air gun is turned on, you can then hold it a few inches above the part that. But the essential tools are almost the same for all pcb repair services. Conductivity ink is not an ideal repair solution for a circuit board that tends to flex or vibrate.

Its answer depends on what kind of repair. Cotton swab and rubbing alcohol. Take off the damaged pad use an exacto knife to gently.

Sometimes you can't solder parts onto a circuit board from the bottom side. It is way easier than you might think. Then carry on with our quick guide to restoring a damaged pcb to.